Pulsar, a Platform for Real-time Industrial Plants Monitoring, Offers a Free Trial at FABTECH Mexico 2024

With over 100 industrial plants being monitored in real-time in Mexico and the United States, Pulsar is a technology 4.0 platform that focuses on improving the productivity of manufacturing companies. Pulsar will be present in this year’s edition of FABTECH Mexico and they will offer a free trial to selected companies.

Pulsar was founded in Silicon Valley by manufacturing and artificial intelligence experts, and it has its main operation offices in Monterrey. They monitor industrial plants for companies like Grupo ABX, Metalsa, Sisamex, and many metalworking companies.

If you want to know more about how Pulsar works, you can visit them in booth 3031 (Hall “H”) during FABTECH Mexico 2024.

Metalworking in Mexico and the Challenge of Agile Modernization

The metalworking sector in Mexico faces new challenges derived from the nearshoring phenomenon in the country, such as complying with international certifications and facing a higher level of competitiveness.

Industrial machinery management is one of the critical topics to address. Commonly, metalworking companies operate many different types of machines, varying in models and ages. A single floor can have a cutting-edge 2023 machine working alongside equipment fabricated 40 years ago that is still functional and productive. This scenario usually creates a data integration issue, since many manufacturing software can integrate into newer machines, but leave older equipment behind.

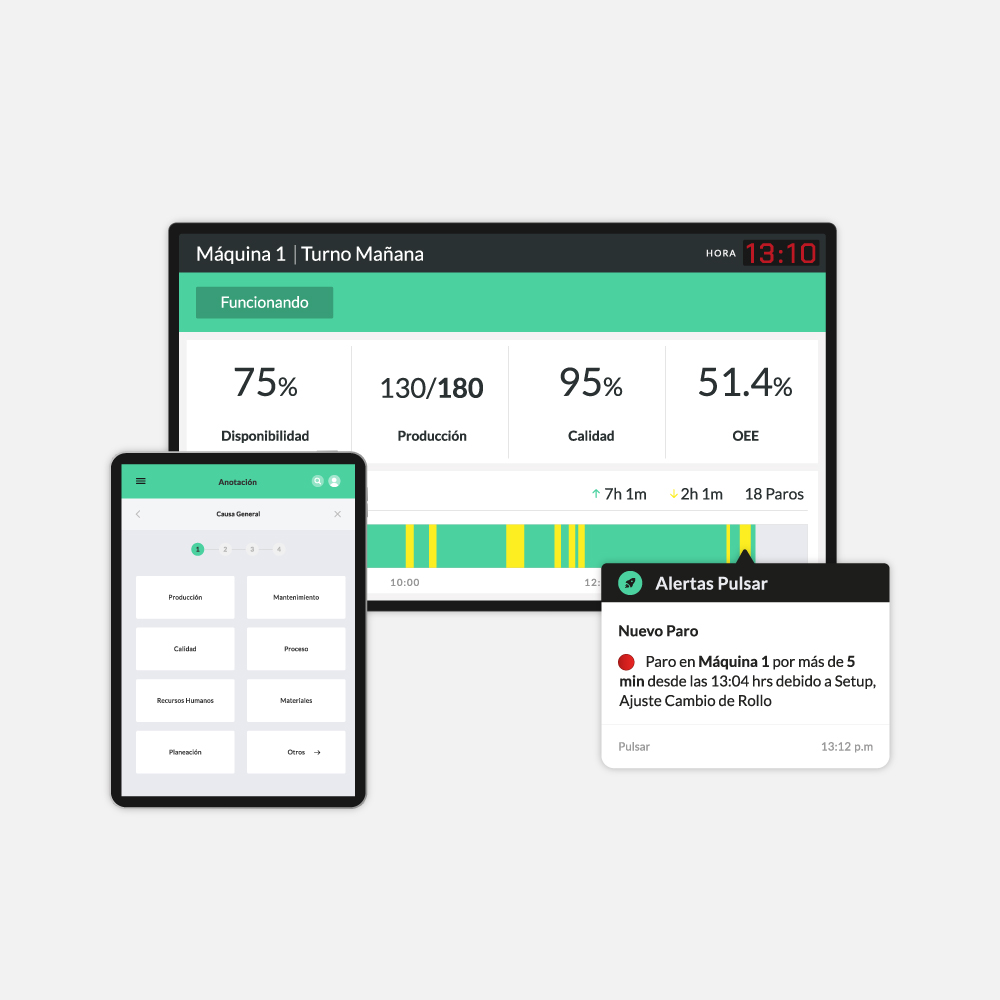

Metalworking companies and overall manufacturers can benefit from a complete view of their industrial plants: it allows them to take full control of their operations and aim for sustainable growth while facing the industry’s current challenges. Leveraging a platform like Pulsar, manufacturing companies can boost their equipment efficiency through industrial sensors and artificial intelligence, no matter their model or age. Pulsar can connect to machinery such as presses, cutting and metal sheet folding machines, and CNCs—among other types—enabling them with real-time monitoring and instant alerts whenever there’s an unscheduled downtime.

Pulsar is a universal, non-invasive system that can be implemented within one visit, which allows companies to see its benefits quickly. The platform can integrate machinery activity data with internal systems such as ERPs, which feeds a 360° view of the industrial plant that can be accessed from a single, integral platform. With this new digital capability and real-time data, manufacturing companies are better prepared for the growth wave in the region.

New dimensions of growth with Pulsar

Pulsar is a reliable solution for metalworking companies that want to modernize their production with agility. The platform offers indicators such as real-time OEE and email, WhatsApp, and SMS alerts for any connected machine.

A key benefit of Pulsar comes from supporting process optimization and continuous improvement programs, which, in turn, improve the efficiency of daily operations. What their clients have achieved:

- • A company that fabricates food industry equipment increased their production by +100% in key production lines

- A steel company achieved a CAPEX reduction of USD 1M in new machinery

- A construction materials company increased its industrial plant efficiency by +30%

With Pulsar’s precise data, manufacturing companies can understand where to focus their efforts to be more productive and scale their production without investing in new equipment.

Want to learn more? Experience its impact firsthand with a free trial

For those interested in this technology 4.0 platform, Pulsar offers a free trial where companies can connect two of their machines and monitor them for a month. Visit Pulsar at booth 3031 (Hall “H”) during Fabtech México 2024 to request a trial.